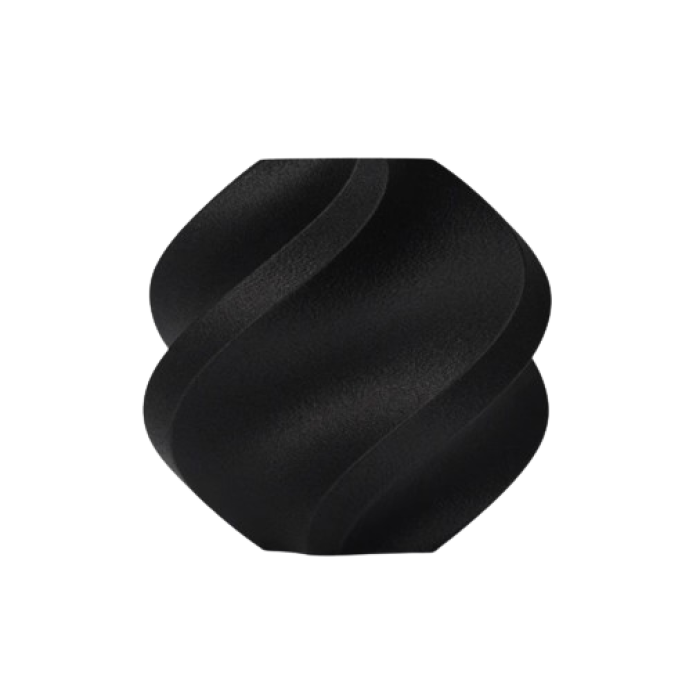

ePA (Nylon)

Development based on nylon 6/66 copolymer; Self-lubricating wear resistance makes it suitable for printing gears; High toughness and impact resistance, with an elongation at break of up to 175%, which can print strong and durable parts with high fracture resistance; Low shrinkage, not easy to warp and crack when printing.

Product Features

Features

- Environmentally friendly, Nylon material

- Printing smoothly, odourless, matte finish.

- High Strength, High Rigidity, Good Toughness, Wear-Resisting, fitting to 3D print industrial parts.

- Compared with Nylon, it has a lower shrink rate and distortion, high accuracy without a warped edge.

- Good flame resistance, Flame-retardant level: UL94-V2.

Shipping Weight

- 1.400 Kg

Description

eSUN ePA (Nylon): Elevating 3D Printing with Unmatched Performance

Unveiling the Power of eSUN ePA (Nylon) Filament

As the world of 3D printing evolves, so does the demand for advanced materials that push the boundaries of what's possible. eSUN's ePA (Nylon) filament, crafted from a nylon 6/66 copolymer base, emerges as a transformative force. Let's delve into the exceptional features that make this filament a game-changer in the realm of 3D printing.

1. Nylon 6/66 Copolymer: The Foundation of Excellence

eSUN's ePA (Nylon) is born from the fusion of nylon 6 and nylon 66 copolymers, creating a material that stands at the forefront of 3D printing innovation. This unique combination forms the basis for the filament's outstanding performance in various applications.

2. Self-Lubricating Wear Resistance: Gears in Motion

Gear up for unparalleled performance with eSUN ePA (Nylon). The filament boasts self-lubricating wear resistance, making it the ideal choice for printing gears that demand smooth and reliable operation. Say goodbye to friction-related issues as ePA (Nylon) ensures a seamless and durable printing experience.

3. High Toughness and Impact Resistance: Built to Last

ePA (Nylon) doesn't just meet expectations; it surpasses them with high toughness and impact resistance. With an elongation at break reaching up to 175%, this filament enables the creation of strong and durable parts that exhibit remarkable fracture resistance. Your prints are not just resilient; they're built to endure the test of time.

4. Low Shrinkage: Warping and Cracking, Begone

Experience the convenience of low shrinkage with eSUN ePA (Nylon). This filament defies the common pitfalls of warping and cracking during printing, ensuring that your creations maintain their integrity. Enjoy a stress-free printing process, knowing that ePA (Nylon) is designed for stability and reliability.

The eSUN ePA Advantage: Beyond Expectations

1. Unmatched Toughness

Step into a new era of toughness with eSUN ePA (Nylon). From prototypes to functional parts, this filament delivers unmatched durability, promising prints that withstand the rigors of real-world applications.

2. Impact Resistance Redefined

Meet the demands of challenging environments with ePA (Nylon)'s high impact resistance. Whether it's intricate designs or robust components, this filament ensures that your prints maintain their structural integrity under pressure.

3. Self-Lubricating Wonder

Navigate the world of 3D printing with ease, thanks to ePA (Nylon)'s self-lubricating properties. Gears and moving parts operate smoothly, minimizing wear and tear, and enhancing the overall longevity of your prints.

4. Excellent Printability

Achieve printing perfection with eSUN ePA (Nylon). The filament's excellent printability opens doors to a seamless and efficient printing experience, allowing you to bring your ideas to life with precision and reliability.

Redefining Possibilities with eSUN ePA (Nylon)

In conclusion, eSUN ePA (Nylon) stands as a testament to the continuous innovation in 3D printing materials. From self-lubricating wear resistance to exceptional printability, this filament redefines what's possible in the world of additive manufacturing. Elevate your prints, embrace durability, and explore new horizons with the transformative power of eSUN ePA (Nylon).

Specification

Print Settings

.png)

-3.png)

-14.png)

-1.png)

-8.png)

-2.png)

-2.png)

-1.png)

- For X1 Series-1.png)

- For AMS inside.png)

-4.jpg)

-4.png)

-4.png)

-3.png)