ABS-GF

Selected:

Product Features

- Enhanced Strength and Stiffness

- Greater Dimensional Stability

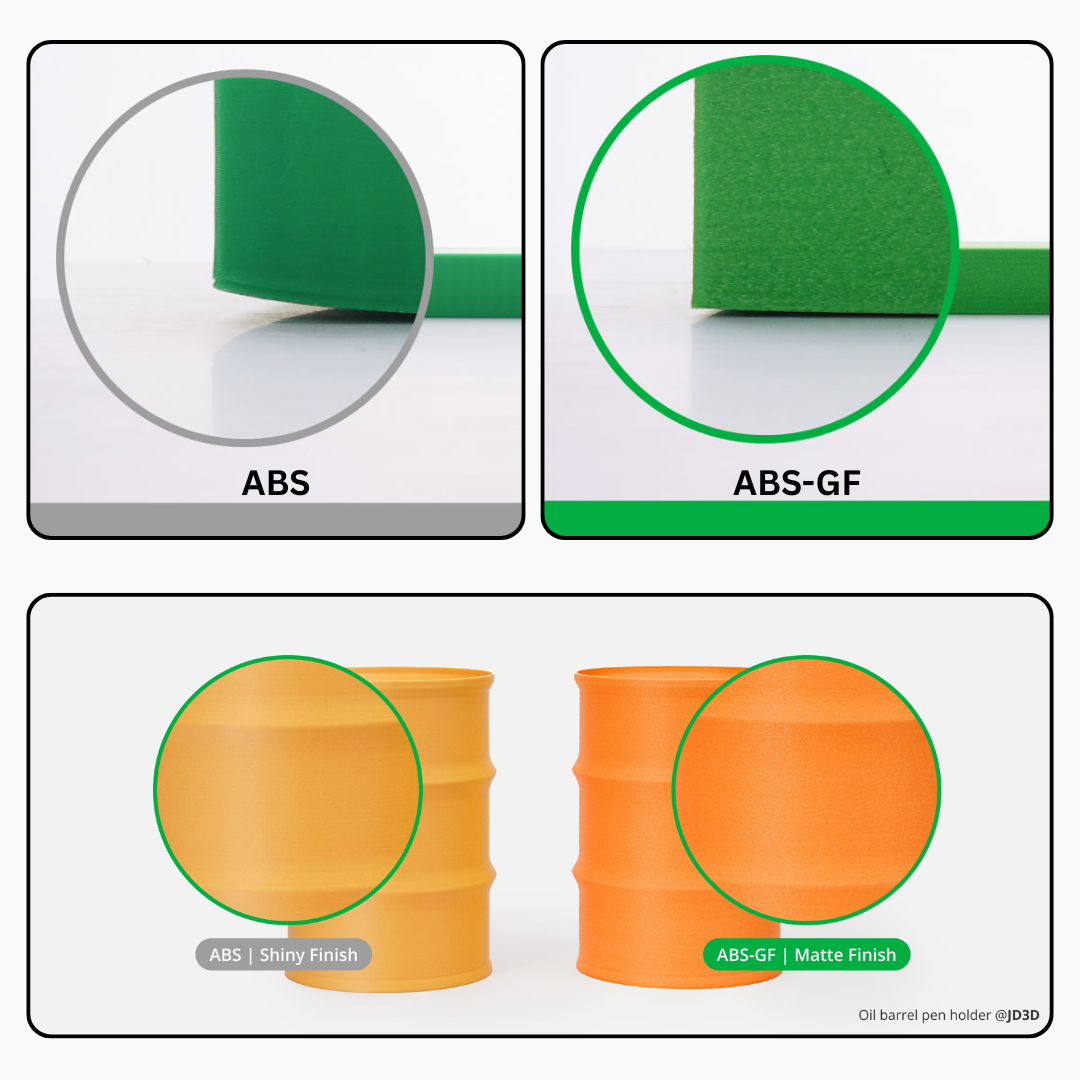

- Fine Matte Finish

- Durability and Water Resistance

- Comes with High Temperature Reusable Spool

- Diameter: 1.75 mm +/- 0.03 mm

Cautions for Use

- 0.2 mm Nozzle Not Compatible

- Enclosure Printers Required

- AMS Compatible

- AMS lite NOT Compatible

- Dry Out Before Use

Note:

- Before printing, please kindly refer to the Printing Tips for optimal results.

Return within 2 days of purchase.

Guarantee Safe Checkout

ABS-GF Complete Specifications

| Composition | Acrylonitrile - butadiene - styrene, glass fiber |

| AMS Compatibility | YES |

| Dry Out Before Use | Recommended |

| Printing Speed | < 180 mm/s |

| Printer Type | Enclosure |

| Toughness (Impact Strength - XY) | 14.5 kJ/m² |

| Strength (Bending Strength - XY) | 68 MPa |

| Layer Strength (Bending Strength - Z) | 46 MPa |

| Stiffness (Bending Modulus - XY) | 2860 MPa |

| Layer Adhesion (Impact Strength - Z) | 5.3 kJ/m² |

| Heat Resistance (HDT, 0.45 MPa) | 99 °C |

| Saturated Water Absorption Rate/% (25 °C, 55% RH) | 0.53 |

| Build Plate | Smooth PEI Plate, Textured PEI Plate |

| Hotend | Hotend with Hardened Steel 0.4mm / 0.6mm (recommended) / 0.8mm |

| Glue | Bambu Liquid Glue, Glue Stick |

| Drying Settings (Blast Drying Oven) | 80 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 240 - 270 °C |

| Bed Temperature (with Glue) | 80 - 100 °C |

| Printing Speed | < 180 mm/s |

| Density | 1.08 g/cm³ |

| Vicat Softening Temperature | 103 °C |

| Heat Deflection Temperature | 99 °C |

| Melting Temperature | 202 °C |

| Melt Index | 7.56 ± 1.4 g/10 min |

| Tensile Strength | 36 ± 3 MPa |

| Breaking Elongation Rate | 6.3% ± 1.2% |

| Bending Modulus | 2860 ± 130 MPa |

| Bending Strength | 68 ± 4 MPa |

| Impact Strength | 14.5 ± 1.5 kJ/m² |

| Drying Conditions | 80°C for 8 hrs. Dry the filament before printing to achieve higher print quality. |

| Warping Prevention | To minimize warping, avoid printing large-sized high infill density models. Use enclosed printers and ensure the build plate is properly applied with glue for better print adhesion before printing. Set lower printing speed and higher heatbed temperature. |

| Ventilation | Similar to ABS, pungent and unpleasant odors may be released during printing. Make sure your printer is placed in a well-ventilated area and use enclosed printers. |

| Additional Resources | For more details please refer to: Common print quality problems and solutions on Bambu WIKI. |