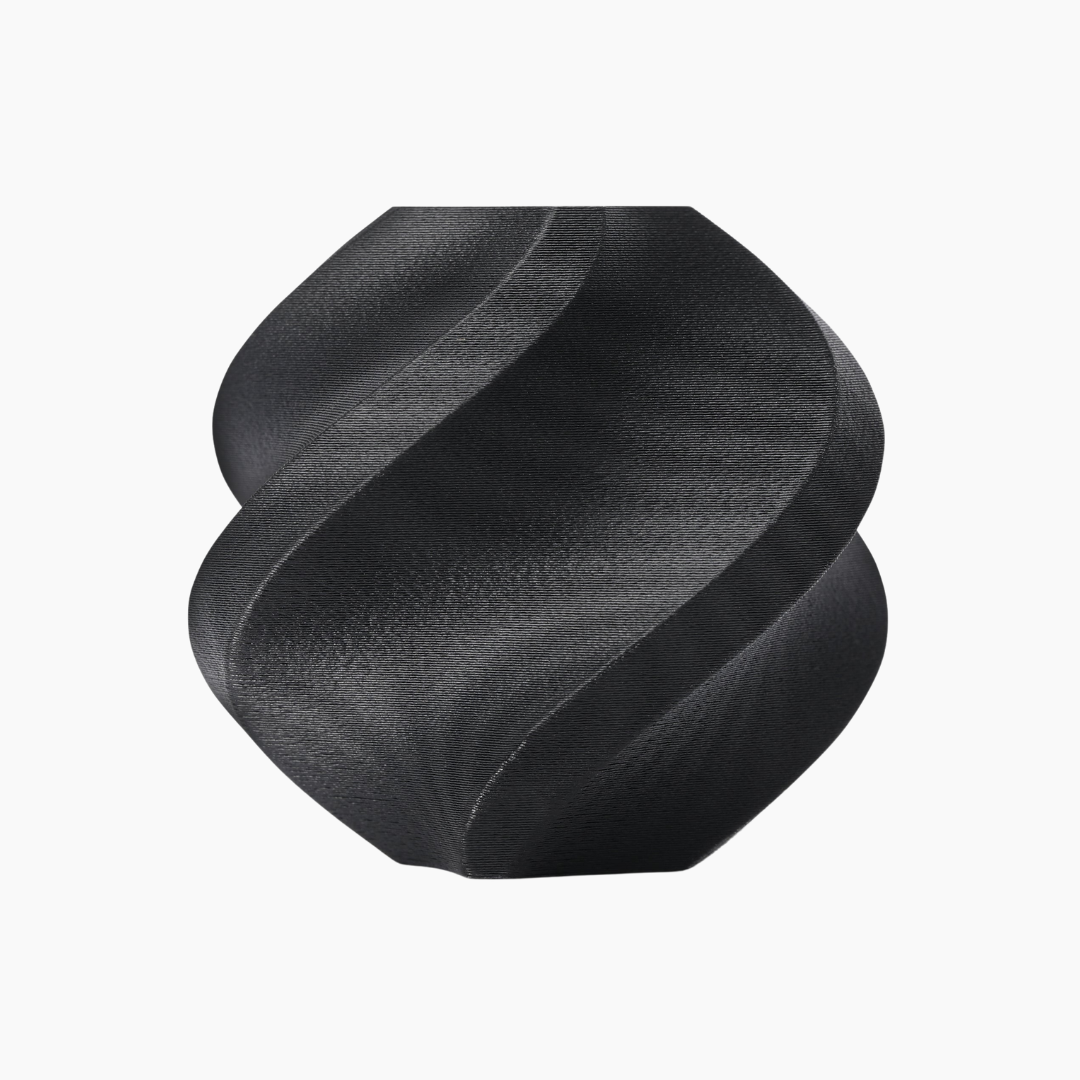

ASA-CF

Selected:

Product Features

- Superior Outdoor Durability

- Optimized for Large Models

- Sleek Matte Finish

- Enhanced Stiffness for High Load-Bearing Applications

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use

- AMS Compatible

- AMS lite NOT Compatible

- Enclosure Printers Required

- 0.2 mm Nozzle Not Compatible

- Hardened Steel Nozzle Mandatory

- Dry Out Before Use

Return within 2 days of purchase.

Guarantee Safe Checkout

ASA-CF Technical Specifications

| Toughness (Impact Strength - XY) | 14.0 kJ/m² |

| Strength (Bending Strength - XY) | 72 MPa |

| Stiffness (Bending Modulus - XY) | 3740 MPa |

| Layer Adhesion (Impact Strength - Z) | 9.4 kJ/m² |

| Heat Resistance (HDT, 0.45 MPa) | 110 °C |

| Saturated Water Absorption Rate (25°C, 55% RH) | 0.33% |

| Build Plate | Smooth PEI Plate, Textured PEI Plate |

| Hotend | Hotend with Hardened Steel 0.4mm / 0.6mm (recommended) / 0.8mm |

| Glue | Bambu Glue Stick |

| Drying Settings (Blast Drying Oven) | 80 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 250 - 280 °C |

| Bed Temperature (with Glue) | 80 - 100 °C |

| Printing Speed | < 250 mm/s |

| Density | 1.02 g/cm³ |

| Vicat Softening Temperature | 108 °C |

| Heat Deflection Temperature | 110 °C |

| Melting Temperature | 210 °C |

| Melt Index | 1.74 ± 0.3 g/10 min |

| Tensile Strength | 34 ± 3 MPa |

| Breaking Elongation Rate | 9.6 ± 1.4 % |

| Bending Modulus | 3740 ± 130 MPa |

| Bending Strength | 72 ± 5 MPa |

| Impact Strength | 14.0 ± 2.2 kJ/m² |