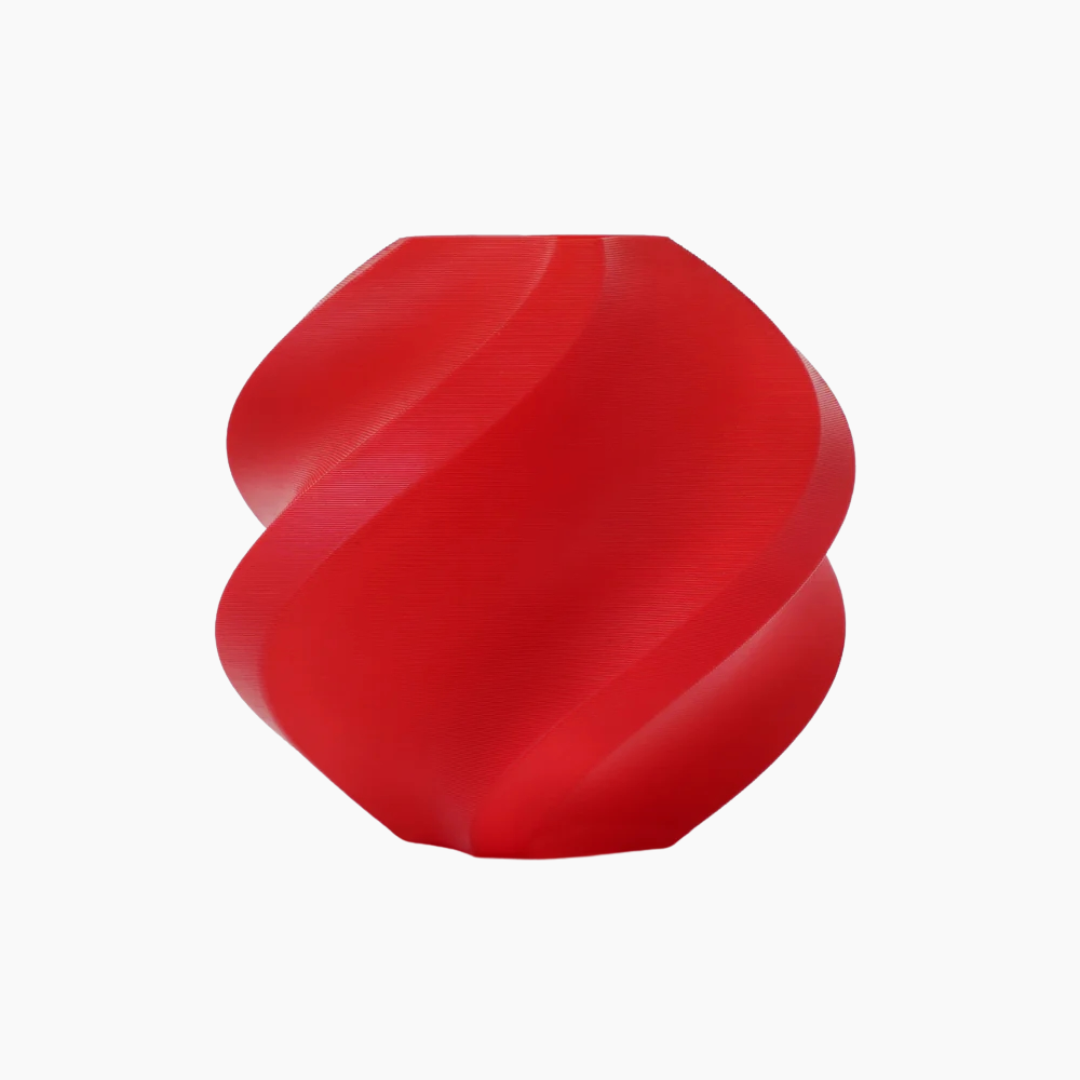

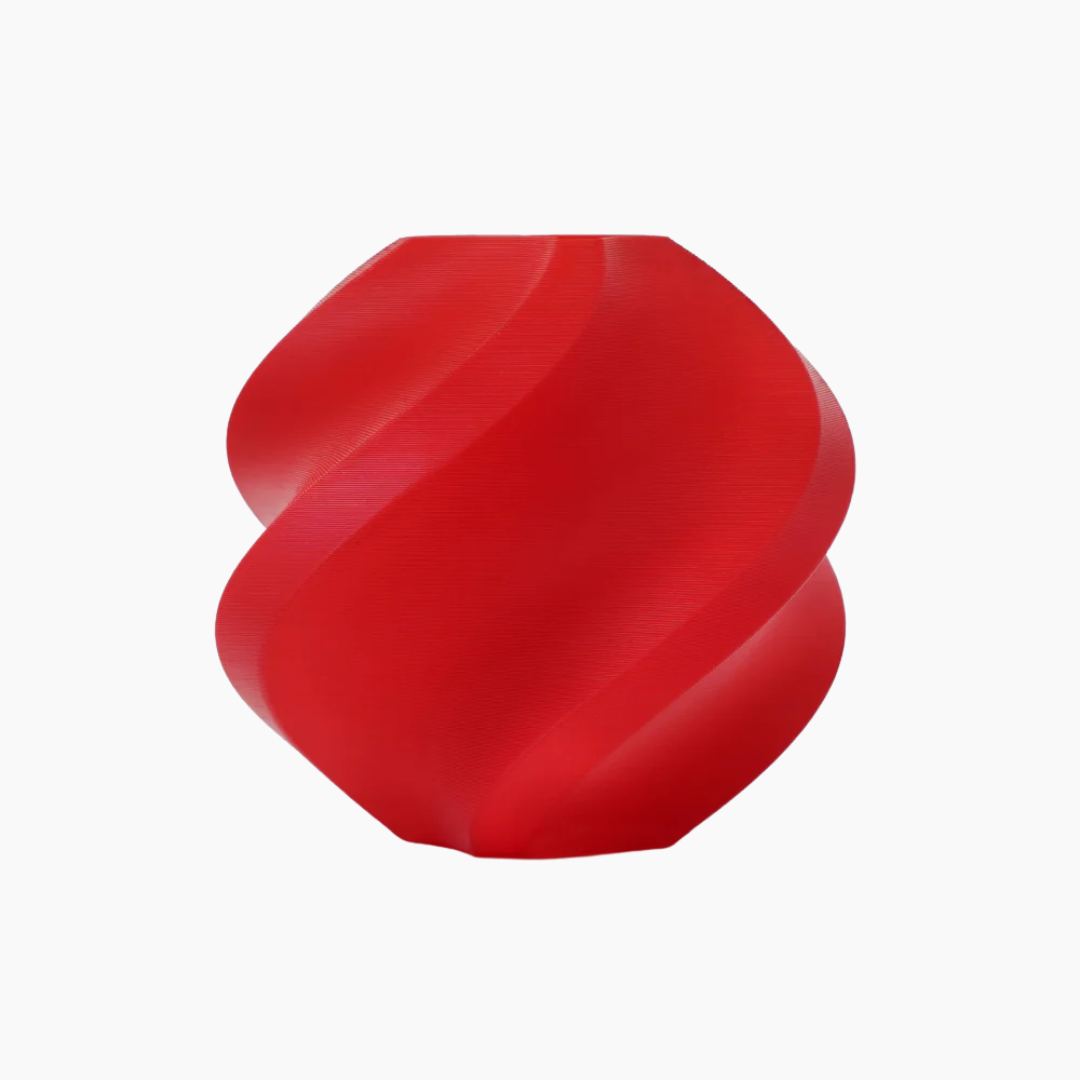

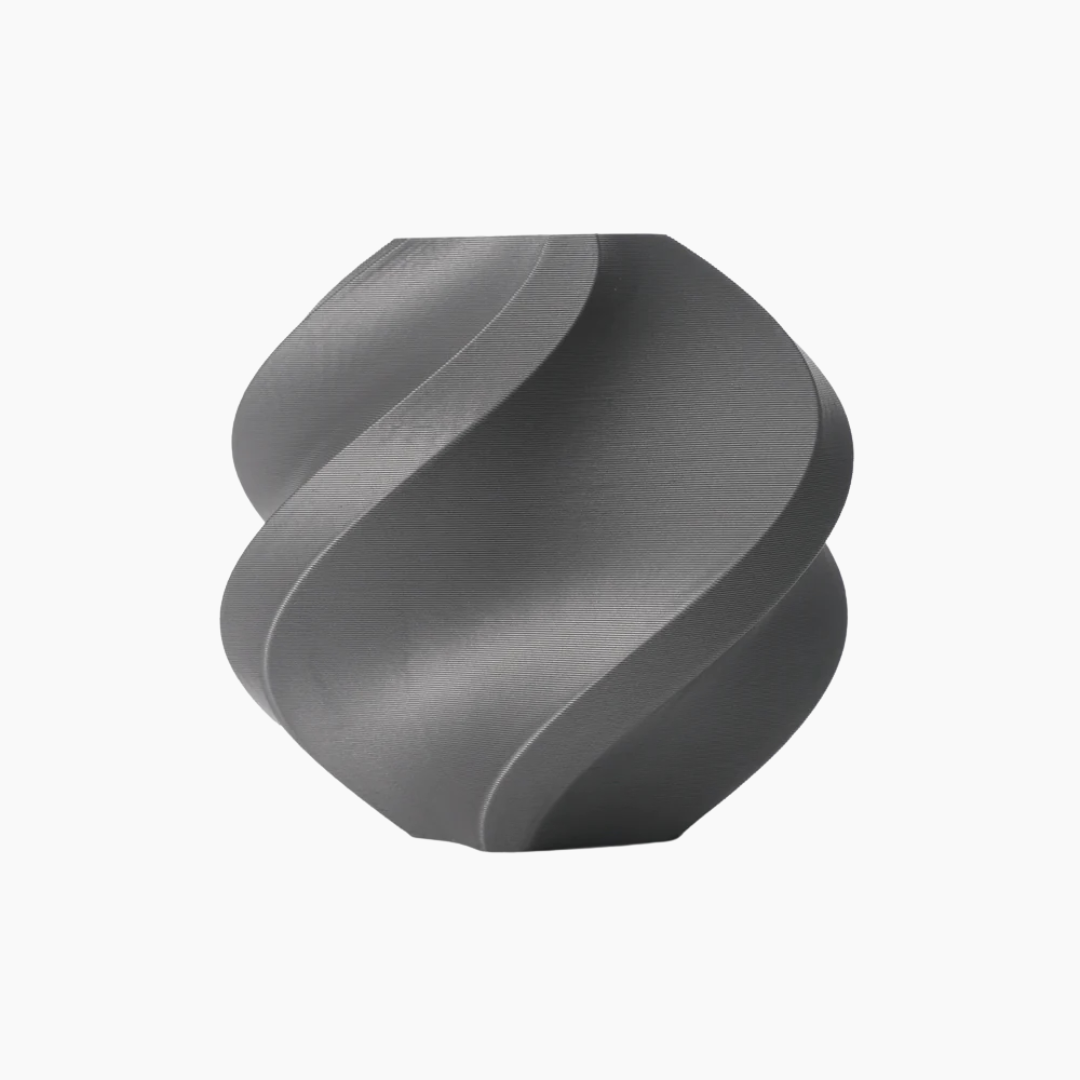

ABS(Refill)

Selected:

Product Features

- Tough and Durable

- Good Heat & Freezing Resistance

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use

- AMS Compatible

- AMS lite NOT Compatible

- Enclosure Printers Required

Return within 2 days of purchase.

Guarantee Safe Checkout

Strong & Durable

Impressive Heat Resistance, Water-Resistant and Tough with High Impact Resistance

RFID for Intelligent Printing

Technical Specifications

| Drying Settings (Blast Drying Oven) | 80 °C,8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed,with Desiccant) |

| Nozzle Temperature | 240 - 270 °C |

| Bed Temperature (with Glue) | 80 - 100 °C |

| Printing Speed | < 300 mm/s |

| Density | 1.05 g/cm³ |

| Vicat Softening Temperature | 94 °C |

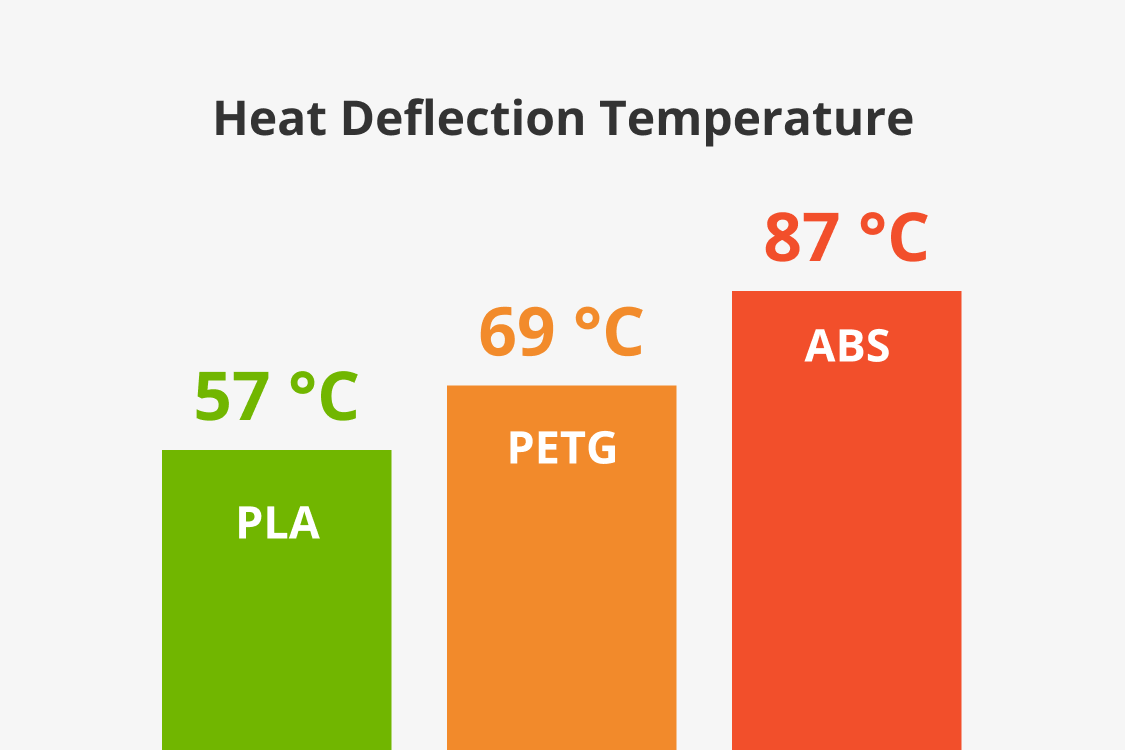

| Heat Deflection Temperature | 87 °C |

| Melting Temperature | 200 °C |

| Melt Index | 34.2 ± 3.8 g/10 min |

| Tensile Strength | 33 ± 3 MPa |

| Breaking Elongation Rate | 10.5 ± 1.0 % |

| Bending Modulus | 1880 ± 110 MPa |

| Bending Strength | 62 ± 4 MPa |

| Impact Strength | 39 ± 3.6 kJ/m² |