Fiberon PPS CF10

Selected:

- Carbon Fiber Reinforcement 3D Material

- High Heat Resistance

- Chemical Resistance

- Flame Retardant

- Moisture Insensitivity & Minimal Warping

Return within 2 days of purchase.

Guarantee Safe Checkout

Technical Specifications

| Nozzle Temperature | 310 - 350°C |

| Build Plate Temperature | 80 - 90°C |

| Printing Speed | Up to 300 mm/s |

| Printing and Keeping Container's Humidity | 70% RH, 23°C |

| Drying Settings (Blast Drying Oven) | 100°C / 10H |

| Density | 1.29 g/cm³ at 23°C |

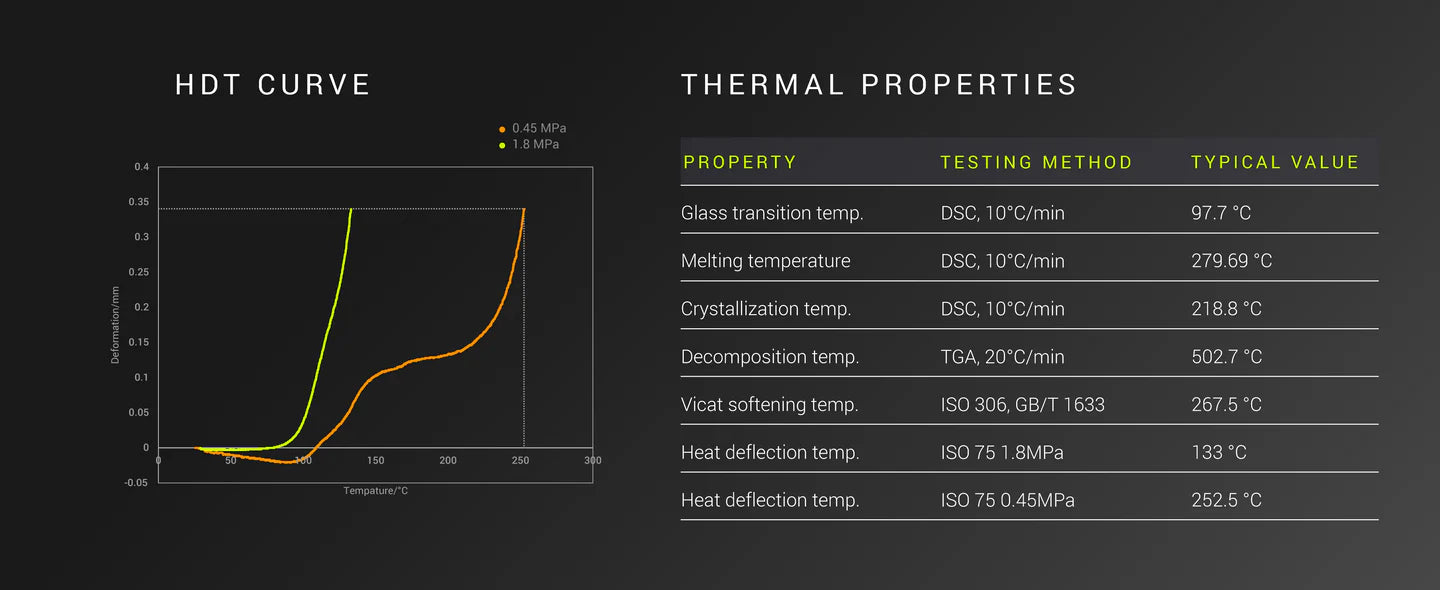

| Vicat Softening Temperature | 267.5°C |

| Heat Deflection Temperature | ISO 75 1.8MPa 133°C |

| Melting Temperature | 279.69°C |

| Melt Index | 26.2 g/10min |

| Tensile Strength | N / A |

| Breaking Elongation Rate | 1.3 ± 0.1% |

| Bending Modulus | 4646.9 ± 136.9 MPa |

| Bending Strength | 94.3 ± 1.9 MPa |

| Impact Strength | 11.4 ± 0.7 kJ/m² |