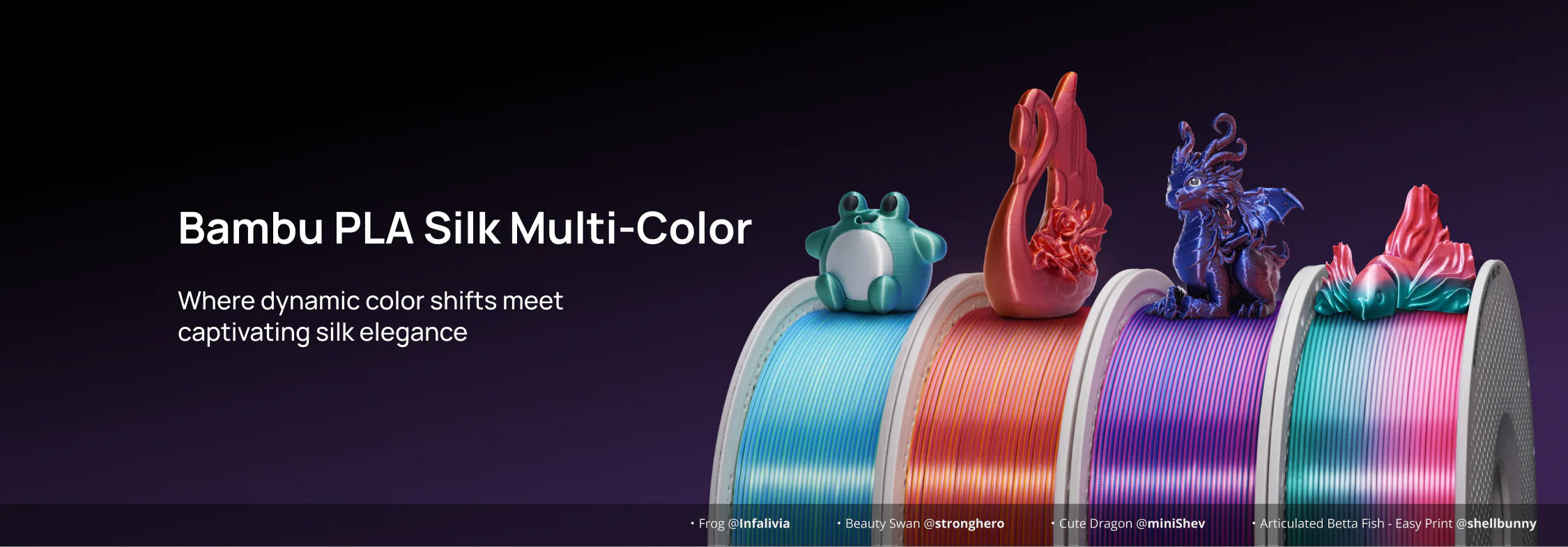

PLA Silk Multi-Color

Selected:

Selling fast! 9 people have this in their carts.

Product Features

- Silk finish with dynamic color transformations

- Comes with basic reusable spool

- Diameter: 1.75mm

Cautions for Use

- All AMS Series Compatible

Note: It's strongly recommended to slow down the Outer wall speed to 40 mm/s to optimize printing results.

Order in the next [hours] Hours [mins] Mins to get it between and

Return within 2 days of purchase.

Guarantee Safe Checkout

PLA Silk Multi-Color

Bambu PLA Silk Multi-Color

PLA Silk Dual Color: Captivating Silk Appearance with Dynamic Effects

PLA Silk Gradient: Smooth, Stunning Color Transitions in One Spool

Technical Specifications

| Drying Settings before Printing (Blast Drying Oven) | 55 °C,8 h |

| X1 Series Printer Heatbed | 65 - 75 °C, 12h |

| Printing and Storage Humidity | < 20% RH (Sealed,with desiccant) |

| Nozzle Size | 0.2, 0.4, 0.6, 0.8 mm |

| Nozzle Temperature | 210 - 240 °C |

| Bed Type | Cool Plate, High Temperature Plate or Textured PEI Plate |

| Bed Surface Preparation | Glue |

| Bed Temperature | 35 - 45°C |

| Cooling Fan | Turn on |

| Printing Speed | < 250 mm/s |

| Retraction Length | 0.6 - 1.0 mm |

| Retraction Speed | 20 - 40 mm/s |

| Chamber Temperature | 25 - 45 °C |

| Max Overhang Angle | 55 ° |

| Density | 1.32 g/cm³ |

| Melt Index | 20.5 ± 1.2 g/10 min |

| Melting Temperature | 152 °C |

| Glass Transition Temperature | 57 °C |

| Crystallization Temperature | N/A |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature (1.8 MPa) | 50 °C |

| Heat Deflection Temperature (0.45 MPa) | 53 °C |

| Saturated Water Absorption Rate | 0.52% |

| Young's Modulus (X-Y) | 1830 ± 210 MPa |

| Young's Modulus (Z) | 1250 ± 140 MPa |

| Tensile Strength (X-Y) | 27 ± 4 MPa |

| Tensile Strength (Z) | 18 ± 4 MPa |

| Breaking Elongation Rate (X-Y) | 3.5 ± 0.6 % |

| Breaking Elongation Rate (Z) | 1.7 ± 0.2 % |

| Bending Modulus (X-Y) | 2370 ± 150 MPa |

| Bending Modulus (Z) | 1840 ± 160 MPa |

| Bending Strength (X-Y) | 66 ± 4 MPa |

| Bending Strength (Z) | 21 ± 5 MPa |

| Impact Strength (X-Y) | 24.5 ± 1.7 kJ/m²;8.2 ± 0.5 kJ/m² (notched) |

| Impact Strength (Z) | 4.6 ± 1.1 kJ/m² |