Bambu Lab P2S Combo

Selling fast! 59 people have this in their carts.

Product Features

- 5-Inch Touch Screen

- AI Failure Detection

- Auto Flow Dynamics Calibration

- Multi-Color Printing

- Cold-Air Cooling

- Active Venting Filament Drying

- 256*256*256 mm³ Print Volume

Return within 2 days of purchase.

Guarantee Safe Checkout

Bambu Lab P2S Combo

Highlights

Featured Collection

5-inch Refreshed Touchscreen

Cold-Air Cooling

Engineering Filaments Ready

Quick-Swap Nozzle

PMSM Servo Extruder

Silky-Smooth Liveview

Auto Flow Dynamics Calibration

Active Venting Filament Drying

AI Error Detection

The User Experience As Good As A Smartphone.

The P2S features a fully upgradedtouchscreenand apowerful processor, running our new intuitivesecond-generation UI. Enjoy smoother interactions, richer graphics, and clearer step-by-step instructions.

5-inch Touch Screen | 2nd-Gen UI

70% More Extrusion Force & Real-Time Error Detection.

PMSM Servo Architecture | DynaSense Extruder

Print Smooth At Every Corner, Always.

Active Flowrate Compensation | Eddy Current Pressure Sensor

ON

OFF

Adaptive Airflow System

50°C Chamber Ready For Engineering-Grade Filaments.

Peace Of Mind, Everytime You Print.

AI Error Detection|2 TOPS NPU

AI Error Detection | 2 TOPS NPU

The P2S introduces advanced AI computer vision that actively detects common printing issues such as spaghetti, nozzle blobbing. It also checks your print start settings, ensuring a safe and accurate start to every print job.

AI Error Detection|2 TOPS NPU

AI Error Detection | 2 TOPS NPU

The P2S introduces advanced AI computer vision that actively detects common printing issues such as spaghetti, nozzle blobbing. It also checks your print start settings, ensuring a safe and accurate start to every print job.

AI Error Detection|2 TOPS NPU

Immediately halt operations if something feels off—giving you full control and added peace of mind.

AI Error Detection|2 TOPS NPU

The P2S introduces advanced AI computer vision that actively detects common printing issues such as spaghetti, nozzle blobbing. It also checks your print start settings, ensuring a safe and accurate start to every print job.

AI Error Detection|2 TOPS NPU

AI Error Detection | 2 TOPS NPU

The P2S introduces advanced AI computer vision that actively detects common printing issues such as spaghetti, nozzle blobbing. It also checks your print start settings, ensuring a safe and accurate start to every print job.

AI Error Detection|2 TOPS NPU

AI Error Detection | 2 TOPS NPU

The P2S introduces advanced AI computer vision that actively detects common printing issues such as spaghetti, nozzle blobbing. It also checks your print start settings, ensuring a safe and accurate start to every print job.

AI Error Detection|2 TOPS NPU

Immediately halt operations if something feels off—giving you full control and added peace of mind.

30-Second Nozzle Swap.

Quick Swap Hotend | 1-Clip Design

No-Lag Liveview & High-Quality Timelapse.

"Stage" Lighting | 1080P High-Rate Camera

Reliable for Fiber-Reinforced Material Printing.

Hardened Steel Nozzle | Hardened Steel Extruder Gear

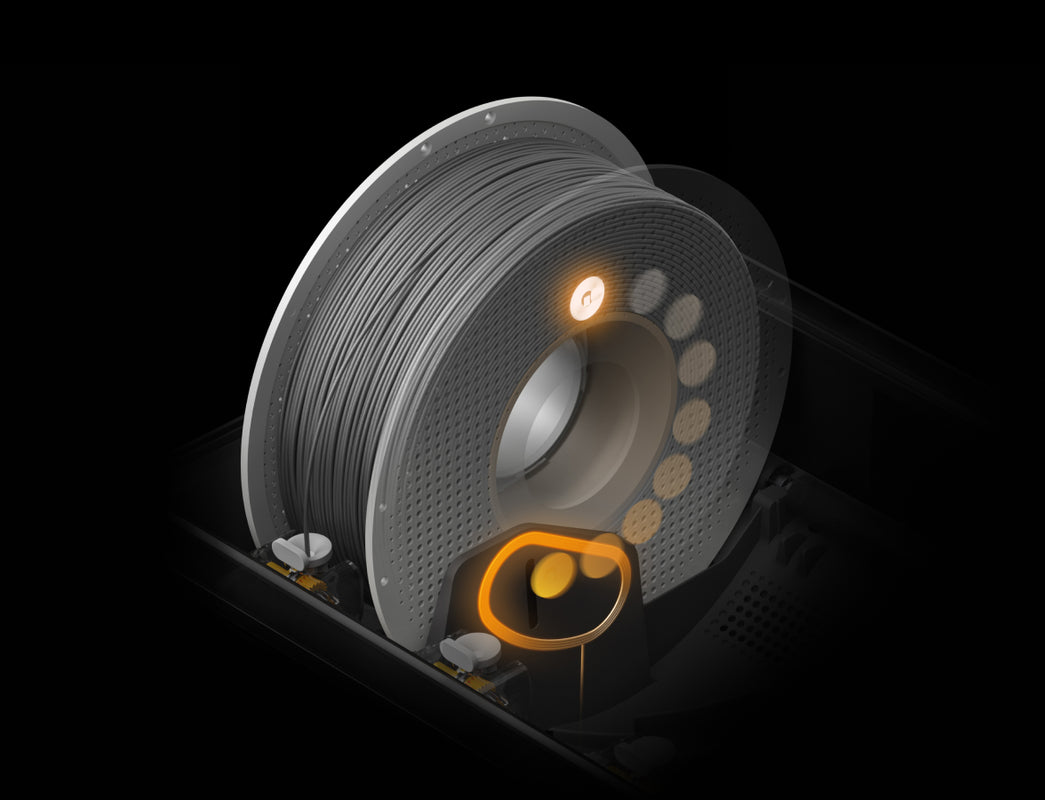

Multi-Color Printing and Drying, All-in-One

Electro-Magnetic Air Vent

Auto-Rotate Drying

RFID Sync

Perfection, Detail by Detail.

The P2S features numerous refinements that enhance the user experience. While these incremental improvements may not be immediately apparent, they embody the level of perfection Bambu Lab constantly pursues.

Built-in 2-in-1 Buffer (equipped with AMS combo)

Effortlessly switch between your AMS and external filament spools for maximum flexibility.

Flat Base Plate

The smooth, flat surface makes it simple to swipe out all residue, keeping your printer clean.

Integrated Lift Handles

Designed for safe and easy transport, these sturdy handles protect your hands and provide a secure grip when moving the printer.

Shatter-Safe Front Glass

Engineered for safety, the front glass is protected by a film built to resist shattering, protecting you and your workspace.

Additional Information

P2S Technical Specifications

| Printing Technology | Fused Deposition Modeling |

| Build Volume (W×D×H) | 256×256×256 mm³ |

| Body Chassis | Plastic and Steel |

| Outer Frame | Plastic and Glass |

| Physical Dimensions | 392×406×478 mm³ |

| Package Size | 490*490*560 mm³ |

| Recommended Space for Printer | 500mm*500mm*950mm |

| Net Weight | 16.4kg |

| Gross weight | 21.33kg |

| Extruder Gear | Hardened Steel |

| Nozzle | Hardened Steel |

| Max Nozzle Temperature | 300°C |

| Included Nozzle Diameter | 0.4 mm |

| Supported Nozzle Diameter | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Filament Cutter | Built-in |

| Filament Diameter | 1.75 mm |

| Extruder Motor | Bambu Lab High-precision Permanent Magnet Synchronous Motor |

| Build Plate Material | Flexible Steel Plate |

| Included Build Plate Type | Textured PEI Plate |

| Supported Build Plate Type | Textured PEI plate, Smooth PEI Plate, Cool Plate SuperTack |

| Max Heatbed Temperature | 110°C |

| Max Speed of Toolhead | 600 mm/s |

| Max Acceleration of Toolhead | 20,000 mm/s² |

| Max Flow for Hotend | 40 mm³/s (Standard Flow Hotend) |

| Test Parameters | 250 mm round model with a single outer wall; Bambu Lab ABS; 280°C printing temperature |

| Filter Type | Activated Carbon - Granulated Coconut Shell |

| VOC Filtration | Supported |

| Particulate Matter Filtration | Supported |

| Part Cooling Fan | Closed Loop Control |

| Cooling Fan for Hotend | Closed Loop Control |

| Auxiliary Part Cooling Fan | Closed Loop Control |

| Supported Materials | PLA, PETG, ABS, ASA, TPU, Support for PLA, Support for PLA/PETG, Support for ABS, PET, PA, PC, PVA, PLA-CF, PETG-CF, ABS-GF, ASA-CF, PA6-CF, PA6-GF, PAHT-CF, PPA-CF, PET-CF |

| Camera | Built-in; 1920×1080; 30 fps HD |

| Door Sensor | Supported |

| Filament Run Out Sensor | Supported |

| Filament Tangle Sensor | Supported |

| Filament Odometry | Supported with AMS |

| Power Loss Recovery | Supported |

| Voltage | 200-240V AC, 50/60 Hz |

| Max Power | 1200 W@220 V / 1000 W@110 V |

| PLA Steady-State Power | 200 W@220 V / 200 W@110 V (PLA printing) |

| Note | To ensure the heatbed quickly reaches the needed temperature (35-110℃), the printer will maintain maximum power for about 3-5 minutes |

| Touchscreen | 5-inch 854×480 Touchscreen |

| Storage | Built-in 8 GB EMMC and USB Port |

| Control Interface | Touchscreen, mobile App, PC App |

| Motion Controller | Dual-core Cortex-M4 and Single-core Cortex-M7 |

| Application Processor | Quad-core 1.5 GHz ARM A7 |

| Neural Processing Unit | 2 TOPS |

| Slicer | Bambu Studio |

| Supported Operating System | MacOS, Windows, Linux |

| Ethernet | Not Available |

| Wireless Network | Dual-Band Wi-Fi |

| Network Kill Switch | Not Available |

| Removable Network Module | Not Available |

| 802.1X Network Access Control | Not Available |

| Wi-Fi Operating Frequency | 2412 - 2472 MHz, 5150 - 5850 MHz (FCC/CE) | 2400 - 2483.5 MHz, 5150 - 5850 MHz (SRRC) |

| Wi-Fi Transmitter Power (EIRP) | 2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC) | 5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC) | 5 GHz Band3: <30 dBm (CE); <24 dBm (FCC) | 5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE) |

| Wi-Fi Protocol | IEEE 802.11 a/b/g/n |

| Heatbed Warm-up | To ensure the heatbed quickly reaches the needed temperature (35-110℃), the printer will maintain maximum power for about 3-5 minutes |