Bambu Lab H2D AMS Combo- 3D Printer

Selling fast! 51 people have this in their carts.

Features

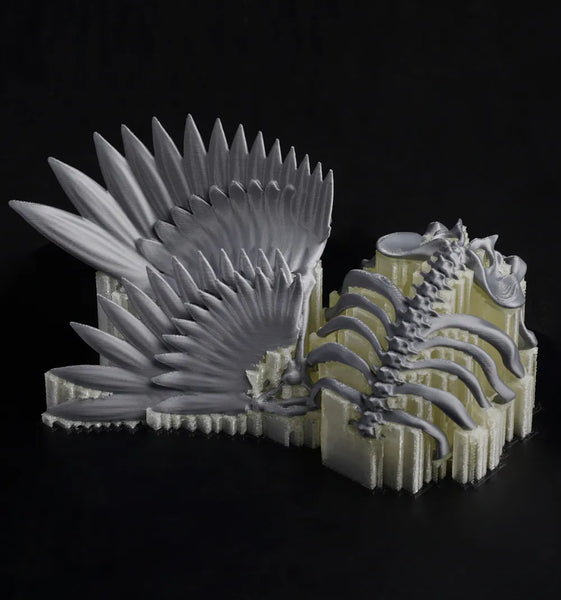

- Dual-nozzle Multi-material 3D Printing

- 350*320*325 mm³ Print Volume

- 5μm Resolution Optical Motion Calibration

- Closed-loop Servo Extruder

- 350°C Nozzle & 65°C Active Chamber Heating

- Voltage Range: 220 V

Return within 2 days of purchase.

Guarantee Safe Checkout

Bambu Lab H2D AMS Combo- 3D Printer

Explore Dual-Nozzle Capabilities

Fast and efficient multi-color printing

Perfect supports with minimal waste, purging and reloading

Flexible and rigid, low cost and exotic materials in one print

King-size Work Zone

Break free from size constraints

With a print volume up to 350mm×320mm×325mm*, creating large-scale projects has never been easier! From laser engraving on sizable objects to printing oversized models, the expanded capacity empowers you to bring even your most ambitious ideas to life.

DynaSense Extruder

Intelligent sensing for precise extrusion control

Bambu Lab's proprietary PMSM servo architecture establishes an intelligent extrusion governance system. It executes 20kHz Torque/Resistance and position sampling to dynamically modulate electromagnetic torque vectors. Stabilizing extrusion and detecting filament grinding and clogging.

350°C Hotend & 65°C Chamber Heating

Unleash the full potential of high performance materials

Equipped with 65°C active chamber heating and a high-temperature hotend reaching up to 350°C, the H2D delivers precise closed-loop temperature control. This advanced system effectively eliminates warping and deformation in high-performance materials, ensuring superior layer bonding and maximizing their full potential.

Pre-Flight Checklist by Al

Peace of mind, every time you print

Prior to each operational cycle, H2D's vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan - Detects debris across the entire print surface. Hardware Configuration Audit - Instantly identifies nozzle dimensions and build plate properties. Digital-Physical Alignment - Automatically verifies consistency between detected hardware specifications and active slicer parameters.

Nozzle Camera

Monitor extrusion at the nozzle tip

The H2D features an Al-backed nozzle camera with macro lens.This intelligent monitoring system continuously tracks extrusion patterns, immediately detecting material accumulation, filament deviations, and extrusion failures.

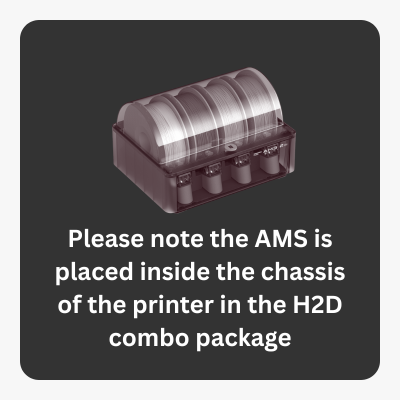

SOTA Filament Monitoring : 15 sensors on one filament path

Unlike legacy systems with single filament run-out detectors, the H2D features comprehensive material flow monitoring. Throughout the AMS-to-nozzle path, 15 strategic sensors form

an intelligent network, continuously tracking five key parameters: feeding velocity, tension, filament tip location, extruder thermal environment, and dynamic extrusion pressure. This establishes an industry-leading filament behavior control system.

Additional Information

Technical Specifications

| Printing Technology | Fused Deposition Modeling |

| Build Volume (W*D*H) | Single Nozzle: 325*320*325 mm³ Dual Nozzle: 300*320*325 mm³ Total Volume: 350*320*325 mm³ |

| Chassis & Shell | Aluminum, Steel, Plastic and Glass |

| Physical Dimensions | 492*514*626 mm³ (Package: 620*620*755mm³) |

| Net Weight | 31 kg (Gross: H2D: 38.5 kg; AMS Combo: 42.3 kg) |

| Hotend | All Metal |

| Extruder Gear | Hardened Steel |

| Nozzle | Hardened Steel |

| Max Nozzle Temperature | 350 °C |

| Supported Nozzle Diameter | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Filament Diameter | 1.75 mm |

| Extruder Motor | Bambu Lab High-precision Permanent Magnet Synchronous Motor |

| Max Speed of Toolhead | 1000 mm/s |

| Max Acceleration | 20,000 mm/s² |

| Standard Flow Hotend | 40 mm³/s (Test: 250mm round, single wall, ABS @ 280°C) |

| High Flow Hotend (Optional) | 65 mm³/s (Test: 250mm round, single wall, ABS @ 280°C) |

| Heatbed Type | Textured PEI plate, Smooth PEI Plate |

| Max Heatbed Temperature | 120 °C |

| Active Chamber Heating | Supported |

| Max Chamber Temperature | 65 °C |

| Working Temperature | 10 °C - 30 °C |

| Part Cooling Fan | Closed Loop Control |

| Auxiliary Part Cooling Fan | Closed Loop Control |

| Chamber Heat Circulation Fan | Closed Loop Control |

| Pre-filter Grade | G3 |

| HEPA Filter Grade | H12 |

| Activated Carbon Filter | Granulated Coconut Shell |

| Touchscreen | 5-inch 720*1280 Touchscreen |

| Storage | Built-in 8 GB EMMC and USB Port |

| Neural Processing Unit | 2 TOPS |

| Live View Camera | Built-in; 1920*1080 |

| Nozzle Camera | Built-in; 1920*1080 |

| Filament Sensors | Run Out, Tangle, Odometry (with AMS) |

| Power Loss Recovery | Supported |

| Basic Materials | PLA, PETG, TPU, PVA, BVOH, ABS, ASA |

| Engineering Materials | PC, PA, PET |

| Reinforced Materials | Carbon/Glass Fiber PLA, PETG, PA, PET, PC, ABS, ASA |

| High-Performance | PPA CF/GF, PPS, PPS CF/GF |

| Primary Software | Bambu Studio, Bambu Suite, Bambu Handy |

| Third-Party Support | Super Slicer, PrusaSlicer, Cura (limited features) |

| Operating Systems | macOS, Windows |

| Control Interface | Touchscreen, Mobile App, PC App |

| Wi-Fi Protocol | IEEE 802.11 a/b/g/n |

| Operating Frequency | 2.4GHz & 5GHz bands (region dependent) |

| Voltage | 100-120 VAC / 200-240 VAC, 50/60 Hz |

| Max Power | 2200 W @ 220V |

| Regional Note | Please purchase the version for your region's voltage |